Pioneering in sectors such as...

Of course we could say we’re specialists in everything. Experts in all areas. Able to supply anything to anyone. But that’s not what we are. We prefer to commit to clients who think and work the same way that we do. We find such clients in many sectors, including the following:

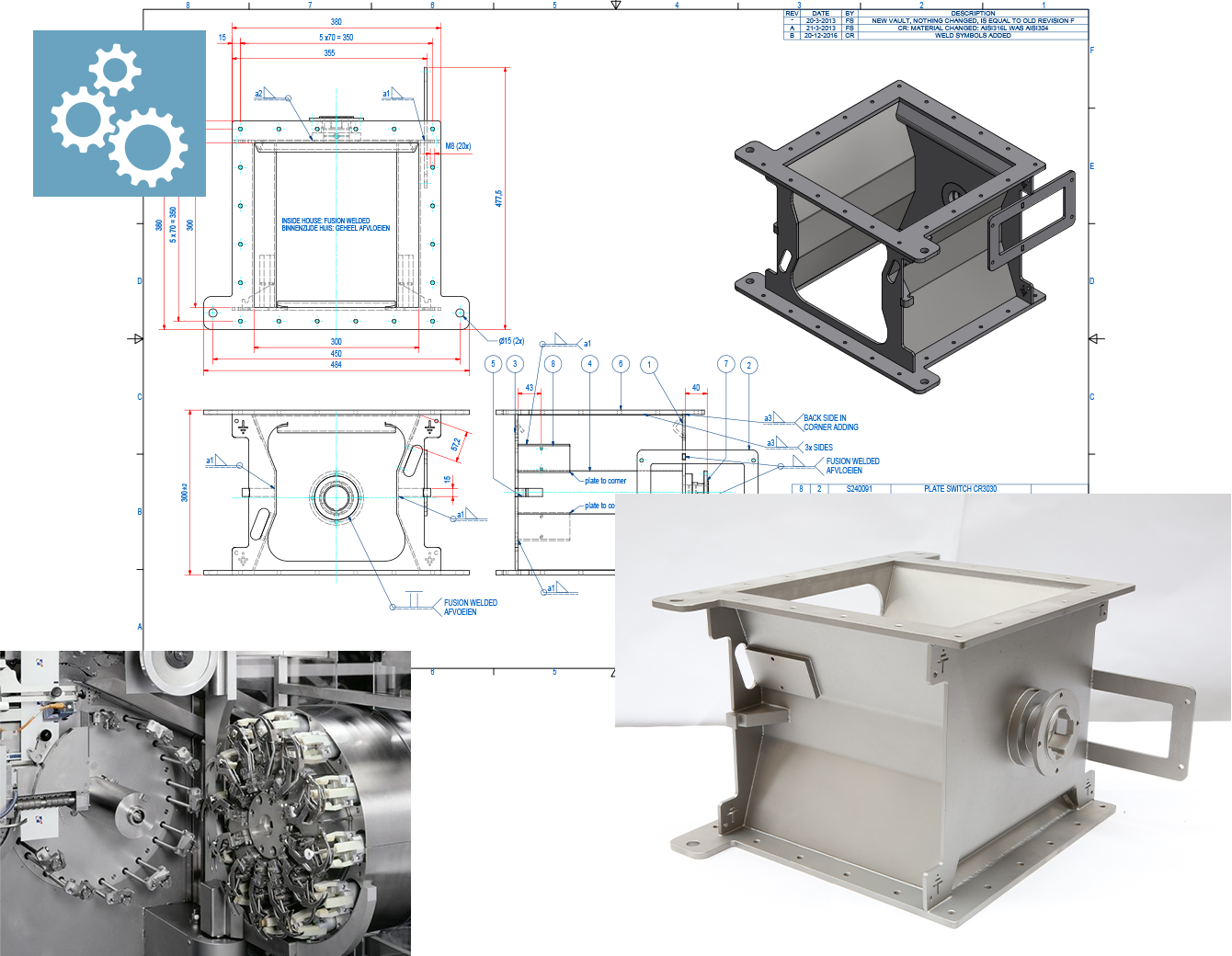

Mechanical engineering

One of the Van Hoof Groep’s strengths lies in the combination of sheet-metal work parts, lightweight structures and the diversity in machining work. This allows us to deliver industry-independent, high-precision mechanical parts in the field of mechanical engineering.

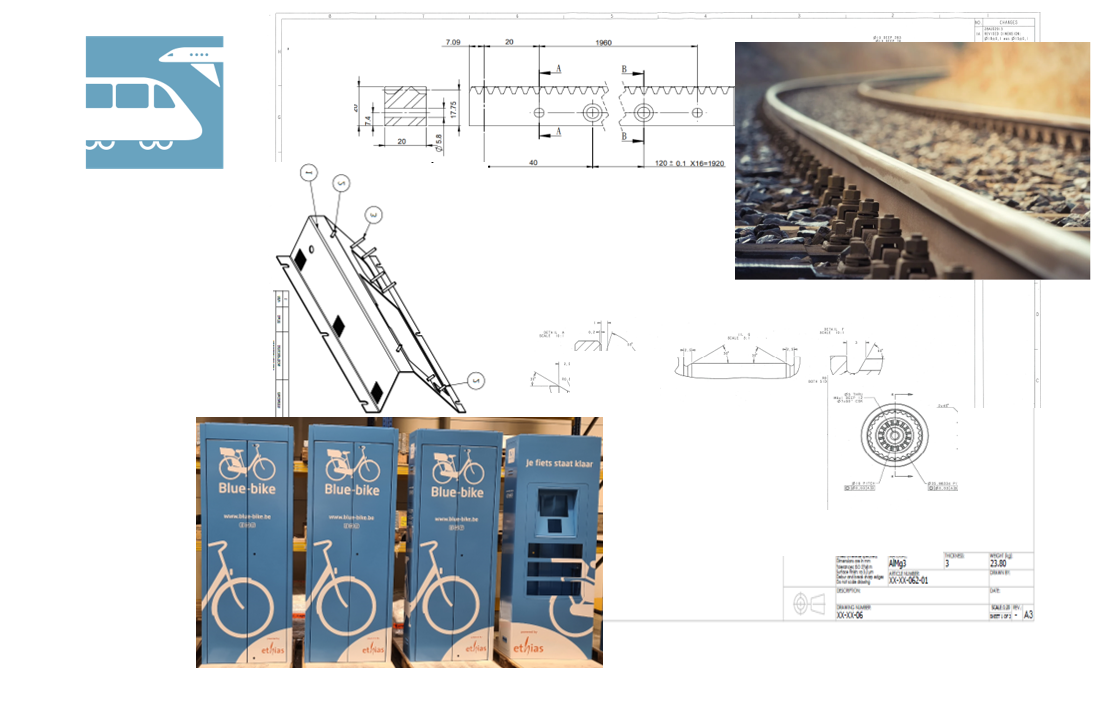

Mobility

Producing drive components for the mobility industry mainly involves prototyping and manufacturing start-up series. All this with a view to series production. This ranges from the luxury car segment and the aviation industry to solutions for public spaces. The latter includes siding, bicycle sheds and digital signing. Many public spaces – both inside and outside – are being improved aesthetically or functionally.

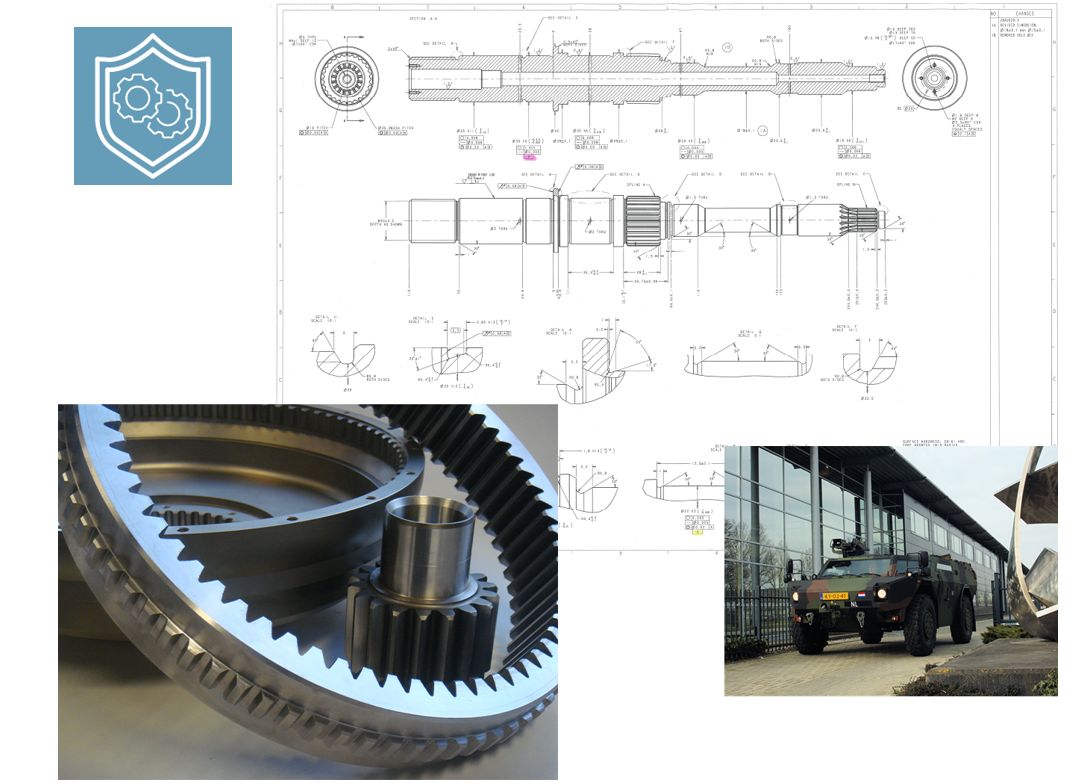

Defense

Producing drive components for the automotive industry mainly involves prototyping and manufacturing start-up series. Our strength lies in the fact that customer demand is converted into production specifications into a specific and tangible part. Whether that is for the luxury car segment, military clients or the aviation industry.

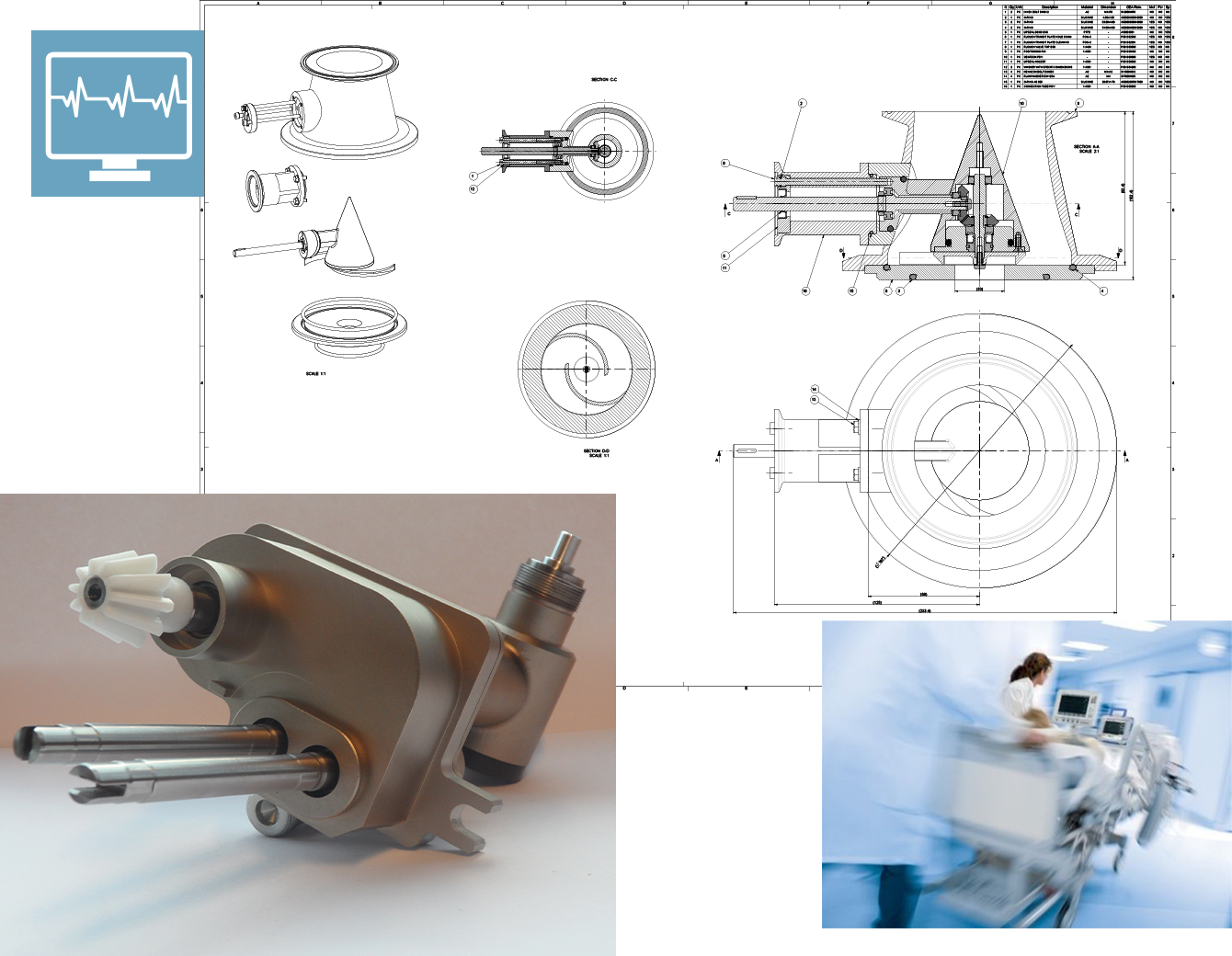

Medical

Parts for ultrasound devices, MRI scanners and microscopes. The Van Hoof Groep co-engineers and develops high-precision mechanical components and parts for the medical industry. Knowledge of various types of materials and imposing a high degree of finishing is of major importance for medical equipment applications.

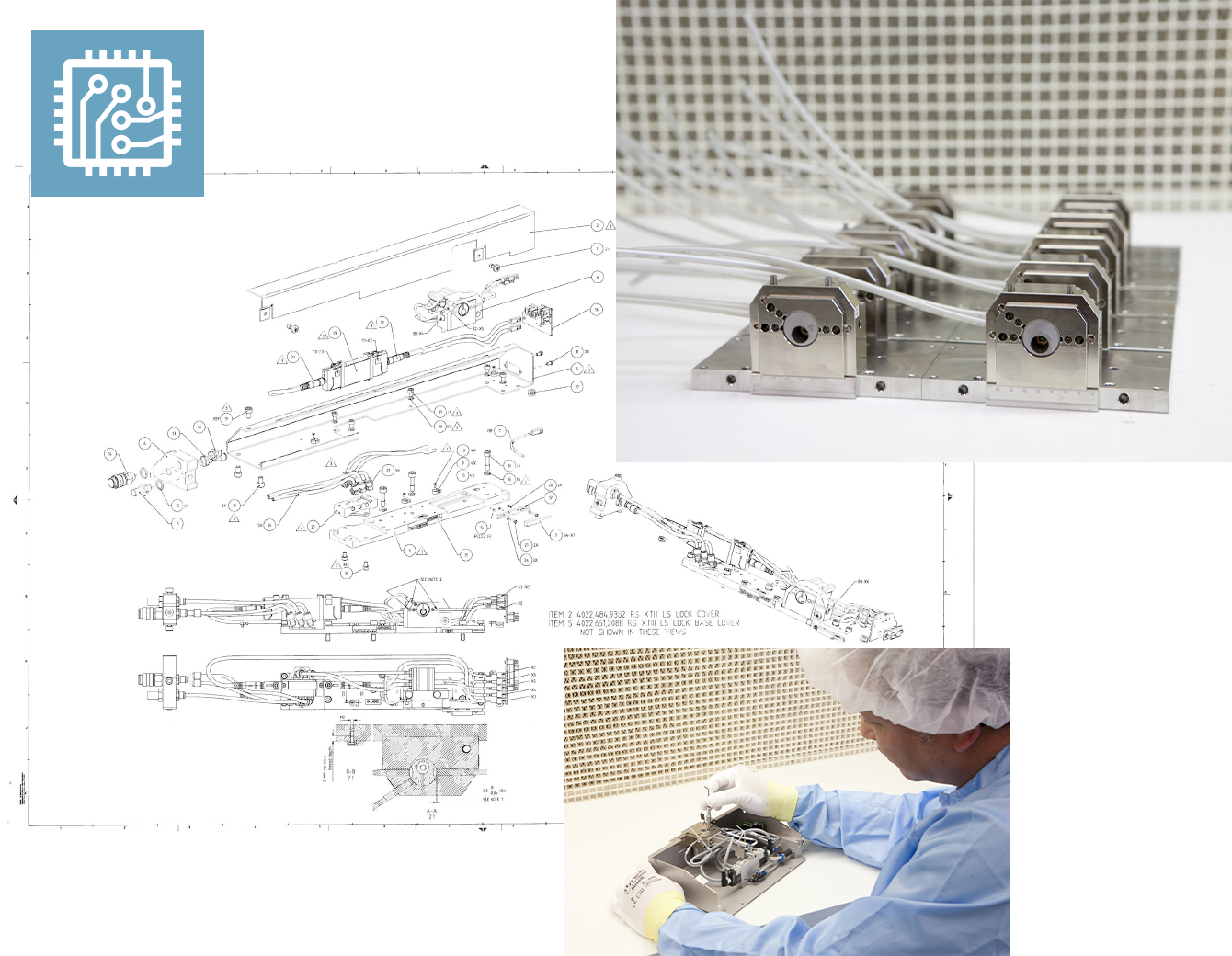

Semiconductor

In the semiconductor sector, the high-level quality of grinding and cleanroom assembly is of vital importance. One of the major advantages is that we offer both the production, as well as assembly and packaging in the cleanroom. In the semiconductor sector, the Van Hoof Groep is particularly geared towards manufacturing precision milling components that are also processed into sub-assemblies in a casing from our own factory.

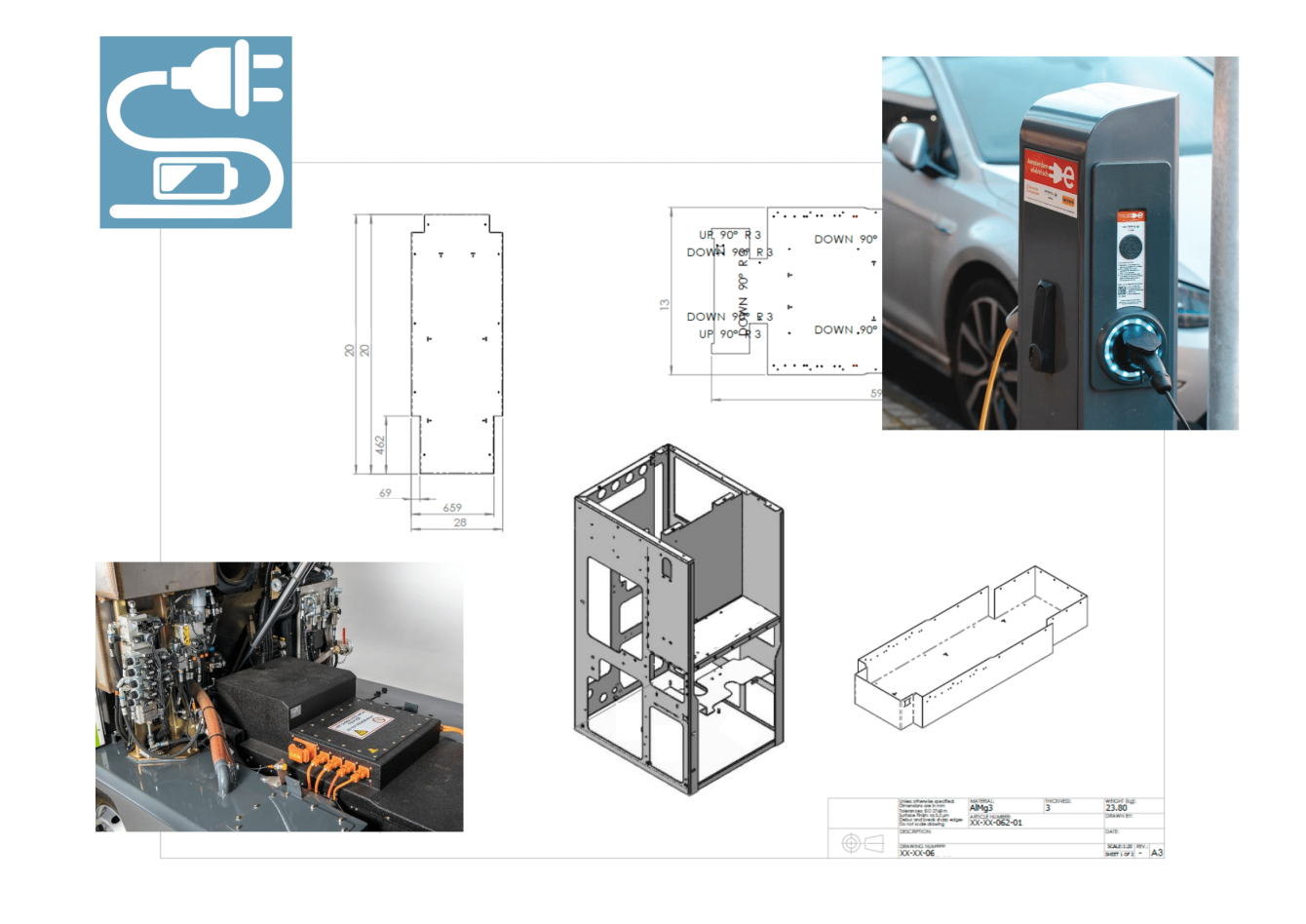

Sustainability

The Dutch road transport is facing a major transition to electrification. Cities will have emission-free zones and vehicles must be able to be charged everywhere. Van Hoof Groep contributes to this transition and, together with customers, produces battery frames, housing for charging stations and specific switch cabinets. In addition, the Netherlands is a major player in the international wind energy market. For example, we produce drive components that are located in the drive boxes between the blades and the generator of wind turbines.